LED technology lighting is already a reality in various areas of our lives. One of its possible uses is in the lighting of industrial buildings. In this article we will look at some of the key points.

Tabla de contenidos

ToggleHistory: traditional lighting

First of all, it is necessary to know the past in order to understand the future. Generally, discharge lamp bells have been used for lighting industrial buildings. Lighting was thus more general, suitable for processes that did not require a great deal of precision.

In order for this lighting to be possible, the installation had to be very tall and have a large surface area. Sheds with a height of 5 or 6 metres had an installed power of around 250W, while 400W power appeared in sheds with a greater height. This process had the lowest installation cost.

With regard to the lights themselves, it should be noted that they have undergone a constant evolution. First, an incandescent lamp was used, to which a gas was added to improve its luminous efficiency. Later, mercury gas appeared, which improved the results of the previous ones, but needed a starting equipment to work. Later, sodium vapour appeared.

Before the advent of LEDs, metal halide lamps were widely used, due to their light output and colour rendering quality. Fluorescent lighting, on the other hand, did not really catch on for the illumination of large areas, as it would take many light points to achieve decent illumination. It would be used for surfaces and one-off processes.

LED lights in industrial hall lighting

The use of LED lights means greater energy savings, as well as economic savings. Compared to halogen lights, the savings can be up to 80%. There are several factors for this:

- Angle of light. Traditional lamps emit light at an angle of 360°. In contrast, LED lights emit light at a specific angle, which makes them more efficient.

- Efficiency. This efficiency means that, with fewer LED lights, we can illuminate the same space.

- Resistance. LED lights are more resistant to adverse situations that may arise, such as possible knocks, dirt or temperature variations.

- Durability. LED lights have a longer useful life than other types of lighting, so there is also a saving in both maintenance and possible replacements.

The different angles of light for an industrial building

There are 3 different angles, so we will have to choose one or the other depending on our needs:

60º. This is a standard symmetrical optic angle that is used for medium distance, in case we need to cover a certain area in a uniform way.

90º. This is a more general purpose symmetrical standard optic angle. It is used to illuminate large areas evenly.

120º. This is a symmetrical extensive optic angle used to illuminate large areas with uniform distribution.

Importance of good lighting in the industrial building

Although at first it may seem a minor detail, lighting is key to different factors in the workplace, as can be seen in the Quantified Benefits of Human Centric Lighting report, carried out by the consultancy firm AT Kearney.

Adequate lighting allows the correct development of the work, being a factor that avoids possible accidents. In fact, the right lighting reduces accidents at work by up to 11%.

Performance and productivity also improve with good lighting. So much so, that productivity in the industrial area improves by 13%.

Our industrial hoods

In NTE Sistemas we can help you to find the best option for LED lighting in your industrial building. Among our products we highlight:

UFEF-LT

These hoods have an elegant and ultra-compact design, with high efficiency and performance, adapted for the most demanding industrial environments. Built in aluminium, with a large surface thermal diffuser and multiple configuration and finish options.

You can find the UFEF-LT hood on the linked page.

UFEF

This professional luminaire is constructed with a pure cold forged aluminium body, designed to ensure the best heat dissipation. These hoods have multiple configuration and finish options that allow them to adapt to any industrial environment.

You can find the UFEF hood model on the linked page.

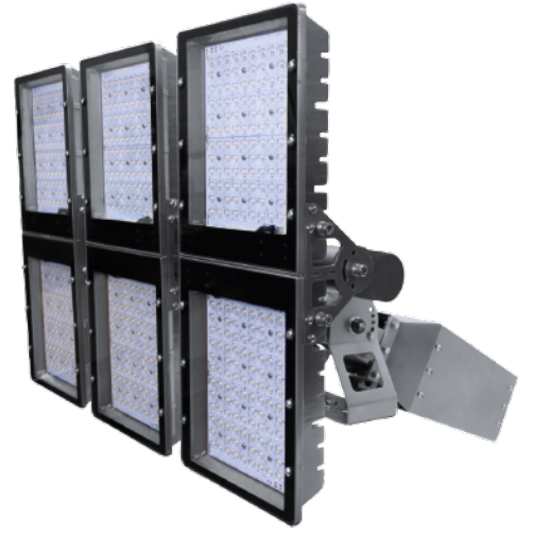

CEF-LT

These high efficiency and high performance hoods are designed for correct operation in any environment (industrial, ornamental lighting, warehouses, etc). In addition, it has the possibility of applying special treatments for environments with caustic atmospheres or high salinity.

You can find the CEF-LT hood on the page we link.